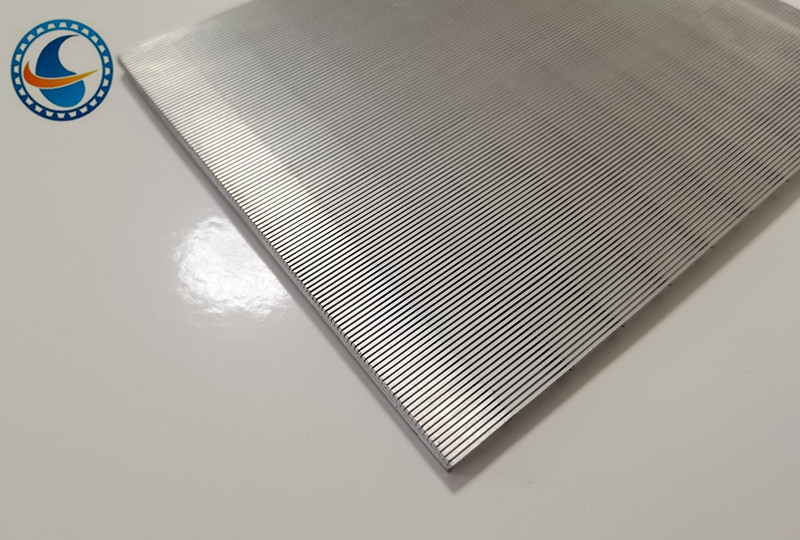

SS 316L Wedge Wire Screen Panels for Filtration and Grain Drying

Wedge Wire Screen Panel Description:

Stainless steel Wedge Wire Screen Panels for Filtration and Grain Drying is a screen formed by welding a wire and a support rod, and the shape of the wire is a Vee-shaped wire, and the shape of the support rod may be Vee-Wire or square wire or round wire.

There is a certain slot between the screen line and the screen line. The value of the slot is provided by the customer or the manufacturer can recommend it based on the size and viscosity of the particular filter object. The slot of the screen is Vee-shaped, the welding point is firm, it is not easy to block, the flowability is good, the permeability is good, and it is widely used in the fields of coal washing, screening, filtration and the like.

The profile wire and support rod can be axial wire or radial wire. It mainly includes internal filtration, external direction

filtration. According to the different usage, we can design the flow direction and shape to meet the application requirements.

Wedge Wire Screen Panel Regular Specifications:

Material: stainless steel 304, 316L, 316L or Duplex Steel 2205 2507, or 90dl, TA2

Slot: 0.025mm - 100mm

Discrepancy: + / - 0.02mm

Dimension: width up to 4000 mm

Length up to 4000mm

| SIZES OF THE WIRE AND ROD |

| WIRE SHAPE |

V |

V |

V |

V |

V |

V |

| Width(mm) |

1.0 |

1.2 |

1.5 |

2.0 |

2.2 |

3.0 |

| Height(mm) |

2.0 |

2.0 |

2.0 |

3.5 |

4.5 |

4.6 |

| ROD SHAPE |

V |

V |

V |

V |

V |

O |

| Width(mm) |

2.0 |

2.2 |

3.0 |

3.0 |

3.2 |

Diameter |

| Height(mm) |

3.0 |

4.5 |

4.6 |

5.0 |

6.0 |

3.0~3.8

|

Wedge Wire Screen Panels Application:

Wedge wire screen panel Widely used in mining, coal, petroleum, fertilizer, grain, salt, environmental protection and other industries. Sieve liquids, powders and other materials. Petroleum, chemical, metallurgy, mining, pharmaceutical purification, drilling fluid purification, etc.

The material of wedge screen, wedge screen, stainless steel welded mine screen: low carbon steel wire, iron wire, stainless steel wire.

Wedge Wire Screen Panels Features:

Wedge-shaped screen, wedge-shaped screen : easy to leak, wear-resistant, corrosion-resistant. The mesh section is trapezoidal. The gap is narrow at the top and wide at the bottom. It is a screen bar made of cold-rolled stainless steel wire. The support bar is welded by automatic mine screen production equipment. The screen seam is uniform, the welding quality is stable, the opening rate is high, the service life is long, and the strength, stiffness and Carrying capacity, it can be made into rigid screening and filtering devices of various shapes.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!