Standard Specifications

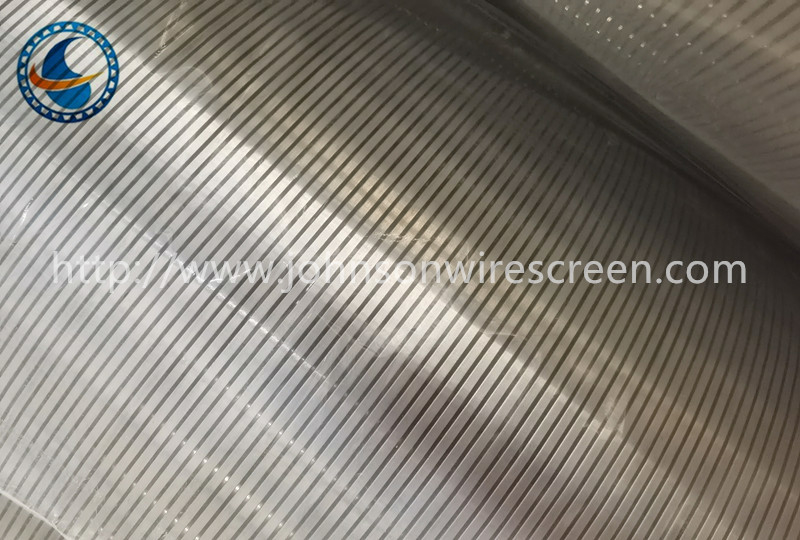

Name: Wedge Wire screen pipe, Continuous Slot Water Well Screen, Johnson screen, Wire warp screen, Wedge wire screen, Screen tube, Slotted tube, Wound screen, Continuous slot screen filter, Sand control screen, Rotary filter drum, Oil screen.

Material: Stainless steel 202, 304, 304L, 316L, Non-magnetic Stainless steel, Low carbon galvanized etc.

Diameter: 3", 4", 6", 8", 10", 12", 14", 16", 18" etc.

Slot: From 0.1-100mm (Normal slot 0.5mm, 0.63mm, 0.75mm, 1.0mm, 1.5mm)

Length: From 100-6000mm (Normal length is 2.9m/3m and 5.8m/6m, to fit container)

Wrap wire: 2*3.5mm, 2.2*3.5mm, 3*4.6mm, 3*5mm, 3*6mm, 3*6.5mm, 3.2*6mm, 4*7mm etc.

Support rod: ø3.0-ø6.0mm round wire, Also can be Vee-shaped wire.

Ends: Welded rings/Plain beveled ends, Male/female threaded, Flange etc.

Use: Water Well, Oil Wells, Waste Water Treatment, Water supply systems, Coal & Mine, Food Processors & Beverage Screens, Environmental protection, Refining & Petrochemical, Architecture & Construction etc.

| Sizes (inch) | OD (mm) | Slot (mm) | Length (m) | Tensile Strength | Collapse Strength | Wrap wire Vee-shaped wire (mm) | Support rod Round wire (mm) |

| 3-1/2 | 88.9 | 1.0 | 2.9 | >22 | 10.2 | 2.0*3.5(Width*height) | ø3.8MM×22 |

| 4-1/2 | 114.3 | 1.0 | 2.9 | >28 | 11.5 | 2.0*3.5(Width*height) | ø3.8MM×22 |

| 6-5/8 | 168.3 | 0.75 | 5.8 | >40 | 12.8 | 2.0*3.5(Width*height) | ø3.8MM×32 |

| 6-5/8 | 168.3 | 1.0 | 5.8 | >33 | 12.8 | 2.2*3.5(Width*height) | ø3.8MM×32 |

| 6-5/8 | 168.3 | 0.63 | 5.8 | >83 | 45 | 3.0*6.0(Width*height) | ø6.0MM×32 |

| 8-5/8 | 219.1 | 1.0 | 5.8 | >34 | 21.9 | 2.2*3.5(Width*height) | ø3.8MM×48 |

| 8-5/8 | 219.1 | 1.0 | 5.8 | >50 | 38.2 | 3.0*4.6(Width*height) | ø4.0MM×48 |

| 8-5/8 | 219.1 | 1.0 | 5.8 | >60 | 46 | 3.0*6.0(Width*height) | ø5.0MM×48 |

| 10-3/4 | 273.1 | 0.75 | 5.8 | >50 | 32.9 | 2.2*3.5(Width*height) | ø4.0MM×55 |

| 10-3/4 | 273.1 | 1.0 | 5.8 | >60 | 39.5 | 3.0*4.6(Width*height) | ø4.8MM×55 |

| 10-3/4 | 273.1 | 1.0 | 5.8 | >100 | 48 | 3.2*6.0(Width*height) | ø5.0MM×55 |

| 12-3/4 | 323.9 | 1.0 | 5.8 | >120 | 37.2 | 3.0*5.0(Width*height) | ø4.0MM×56 |

| 14 | 355.6 | 1.0 | 2.9 | >80 | 37.8 | 3.0*5.5(Width*height) | ø4.0MM×59 |

| 16 | 426 | 1.0 | 2.9 | >80 | 37.5 | 3.0*5.5(Width*height) | ø4.0MM×64 |

Special specification can be made according to your need!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!