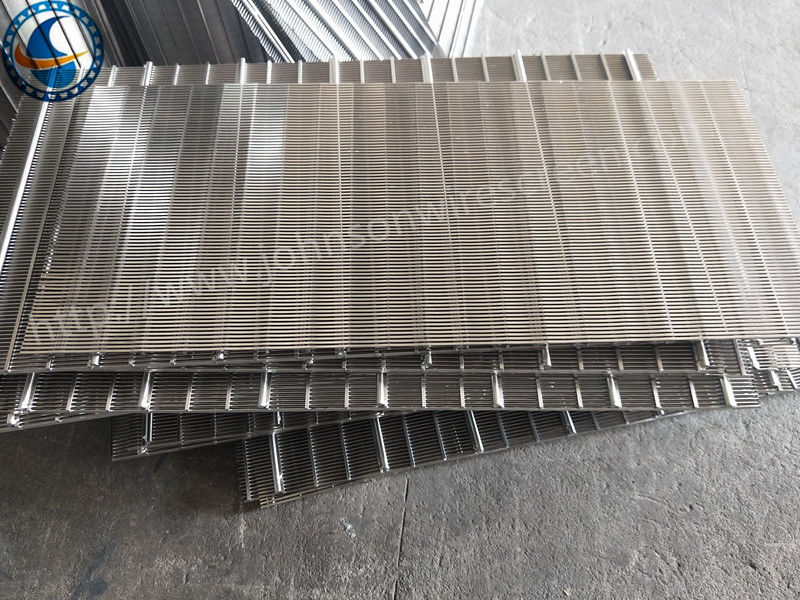

Stainless Steel 304 Johnson Vee Wedge Wire Screen Export To Thailand

Product Description:

Stainless Steel 304 Johnson Vee Wedge Wire Wrapped Screen Plate is welded by Vee-wire and support rod.

There is a fixed value slot between each Vee-wire.

The support bar can be a round wire or a triangular wire or a trapezoidal wire.

The maximum size of the screen can be 4000*4000mm.

The frame or support plate can be added to the bottom or the surrounding of the screen according to the customer's needs. It can also make a certain arc according to customer requirements to meet the needs of use.

The surface of the screen is evenly spaced, the solder joint is firm and the permeability is good.

Specification:

| Material |

Stainless steel |

| Grade |

304 |

| Wedge Wire |

2 × 3.5mm,or as your request |

| Slot Size |

1.25 mm,or as your request |

| Width |

up tp 4000mm |

| Length |

up to 40mm |

| Type |

screen plate |

| Wire size |

2*3.5 mm |

| Support rod |

3*4.6 mm |

| Wire shape |

Vee-shaped |

Regular Specifications:

Material: stainless steel 304, 304L, 316L etc.

Slot: 0.1mm - 10mm

Discrepancy: + / - 0.05mm

Dimension: Width up to 4000 mm

Length up to 4000mm

Specification of the wrap wire:1 * 2 mm, 2 * 3 mm, 2.2 * 3.5 mm, 3 * 4.6 mm and so on.

Specification of the rod: 2 * 3 mm, 3 * 4.6 mm, 3 * 5 mm, 4 * 4 mm ( square shape ) and so on.

Special specification can be made according to your need.

Advantages:

Stainless Steel 304 Vee-Wedge Wire Screen Flat have many advantages as below:

1. V-Shaped Slots:

Openings shaped like a "v" that open toward the inside of the well tend to allow the particles that are just barely smaller than the width of the slot pass. In other shapes of openings, these particles would get caught in the screen and clog it.

2. Very Large Open Area:

This design gives continuous slot and hence the% open area for water to enter is more than 2 times that of conventional slotted pipes of any size and slot opening. This allows more water to enter at much lesser frictional head loss and the efficiency of tube well is improved appreciably.

3.Energy Saving:

Due to reduce frictional head losses and increased discharge, the pump load reduces the power required to pump same quantity of water. Power saving of around 20-25% is observed.

This size is made for one client from Thailand.

We can make any other size according to your drawing.

Pls feel free to contact me if you have any questions.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!