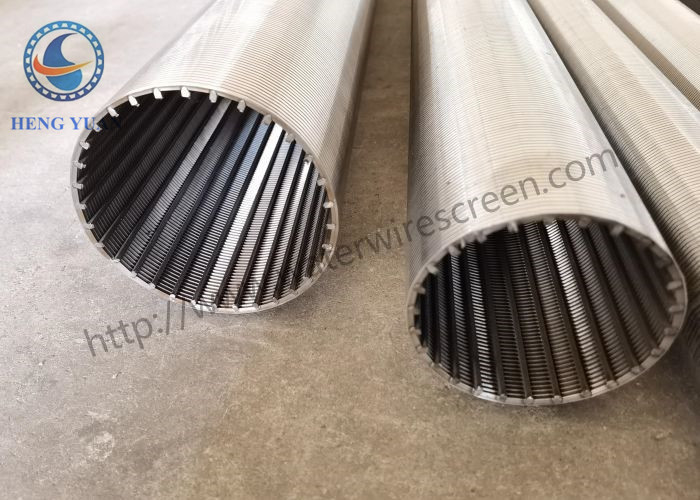

Stainless Steel 304 Johnson Wedge Wire-wound Screen For Water Well

Product Description:

The wire-wound screen is a perforated water filter. It can be used with deep well pumps and submersible pumps, and can also be used in water treatment equipment, environmental protection, desalination of seawater into industrial water and domestic water, tap water treatment, water softening treatment, petrochemical industry, and terminal filtration of petroleum products. And the filtration of chemical acid and alkali liquid, the recovery and filtration of organic solutions such as alcohol.

The wire-wound screen uses a full-process welding process to ensure the strict continuity of the product and form a uniform gap size. Compared with the welding process commonly used in China, the Schroeder screen is smooth in terms of surface smoothness and uniform gap. There are certain advantages in terms of product quality and product quality, thus ensuring high-quality and efficient use by users!

Manufacturing process:

1. The Schroeder screen adopts the world's advanced full-wound welding production process, and is made of special trapezoidal wire and triangular wire windings welded on a set of supporting wires arranged in a circle. Full-process welding, the wire is connected to the support rod by electric welding, which ensures the strict continuous integrity of the product, so that it forms an ideal gap size and has the performance of maximum high pressure.

2. The production of Schroeder wire-wound screens can be made of different raw materials according to different needs, mainly including: 304 type and 316 type stainless steel, Monel copper-nickel alloy, galvanized or ungalvanized low carbon steel and Thermoplastic materials, mainly polyvinyl chloride and acrylonitrile-butadiene-styrene or alloys based on them. Some other highly specialized materials are available for particularly aggressive water quality.

3. The slit opening of the Schroeder wire-wound screen is formed by the continuous winding of the wire to form the ideal gap size. The whole process is monitored by the computer console, and the entire production process is manually supervised. Each production link is used by professional production personnel. Advanced and sophisticated professional equipment for production. The individual slot spaces of a Schroeder wire screen can vary during manufacture. In fact, even a single section of the screen can be made with different sized gaps when the geological requirements become worse. This is conducive to the maximum application of the hydraulic conductivity of each layer. Each production link of this product is produced by professional production personnel using advanced and sophisticated professional equipment. Product specifications and raw materials can be specially customized according to customer needs. All products are strictly inspected in accordance with authoritative product standards to ensure product quality, thereby ensuring the interests of our customers and obtaining the highest production efficiency with the most economical investment.

OEM service:

Please tell us the specification of the wire screen you need, and we will help you to process the high quality products.

Custom range

Filter pipe material: mainly stainless steel, carbon steel galvanized, carbon steel spray or other customer requirements material.

Gap: 0.1mm-15mm, arbitrarily selected screen size to meet different construction requirements.

Diameter: 2 " 3 " 4 " 5 " 6 " 8 " 10 " 12 " 14 " 16 " 20 ". 29 mm - 1000 mm.

Length: 2.9 M, 5.85 M. Up to 6 M.

Connection form: groove connection/weld ring connection or thread connection.

Pictures:

Package:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!